Mô tả sản phẩm

Amec Group Complete Auto Floating Fish Feed Manufacturing Plant 0.5-2t/H

Floating fish feed manufacturing plant can be used to produce corn, wheat, starch, soybean cake, oil cake powder, grain cereal flour, trace elements and fishmeal etc for fish. It can be used for frog, aquatic product, ornamental fish and pet feed farming,middle size and small size feed factory.

Main Materail of Floating Fish Feed Manufacutring Plant:

Wheat meal, maize powder, soybean meal, cottonseed meal, fish meal, bone meal, corn meal, meat meal, etc.

Moisture of raw material:20%-25%

Oil content: ≤10%

Starch content: ≥30%

Raw material type: powder

Features of Floating Fish Feed Manufacutring Plant Machinery:

1. This dry type floating fish feed machine is widely used for producing floating feed pellets of all kinds of aquatic animal.

2. Advanced technology and humanized design ensures easy operation and reliable performance.

3. High efficiency, low power consumption

4. Screw sleeve of this floating fish feed machine adopts 40Cr, which guarantees long service life.

5. Different moulds can be chosen to make pellets with different diameters and shapes.

6. Feed pellets diameter can be 0.9-20mm.

Working Process of Fish Feed Production Plant:

Technological procedure:

Starting Materials → mixing → transferring → extrusion puffing → transferring → drying → cooling → screening → spraying oil → seasoning → packaging

Equipment configuration of Fish Feed Production Plant:

Mixer → transfer unit → extruder → elevator → dryer → cooler → vibrating screen → elevator → oil spraying machine → automatic packaging machine

Main Parameters of Dry Type Floating Fish Feed Production Plant Extruder:

| Model | Capacity(kg/h) | Main Power(kw) | Feeding Power(kw) | Cutting Power(kw) | Screw Diameter(mm) |

| DGP-40 | 30-40 | 5.5 | 0.4 | 0.4 | 40 |

| DGP-50 | 60-80 | 11 | 0.4 | 0.4 | 50 |

| DGP-60 | 120-150 | 15 | 0.4 | 0.4 | 60 |

| DGP-70 | 180-250 | 18.5 | 0.4 | 0.4 | 70 |

| DGP-80 | 300-350 | 22 | 0.4 | 0.6 | 80 |

| DGP-90 | 400-450 | 37 | 0.4 | 1.5 | 90 |

| DGP-120 | 500-700 | 55 | 0.4 | 2.2 | 120 |

| DGP-135 | 800-100 | 75 | 0.4 | 2.2 | 133 |

| DGP-160 | 1200-1500 | 90 | 0.75-1.1 | 3.0 | 155 |

| DGP-200 | 1800-2000 | 132 | 1.5 | 3.0-4.0 | 195 |

Final Floating Fish Feed Pellets:

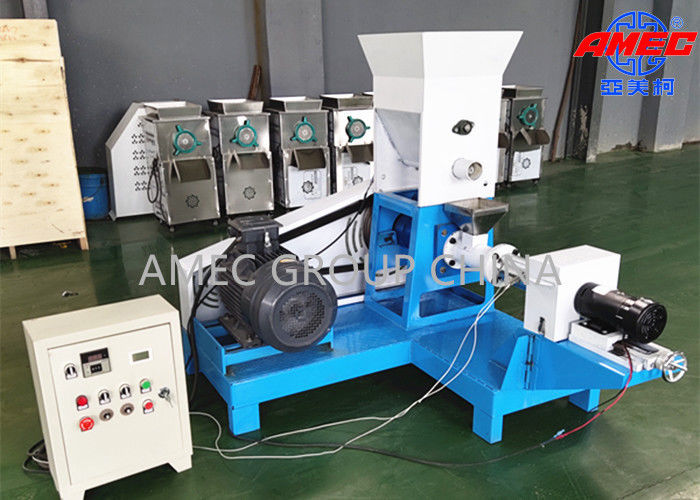

Structure and Spareparts of Dry Type Floating Fish Feed Manufacturing Plant Extruder:

More pictures for Dry Type Floating Fish Feed Manufacturing Plant Extruder:

Installation of Floating Fish Feed Manufacturing Plant: